Zinc Oxide Silica Composite

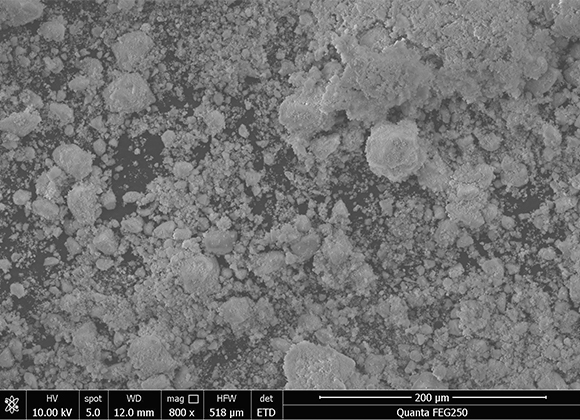

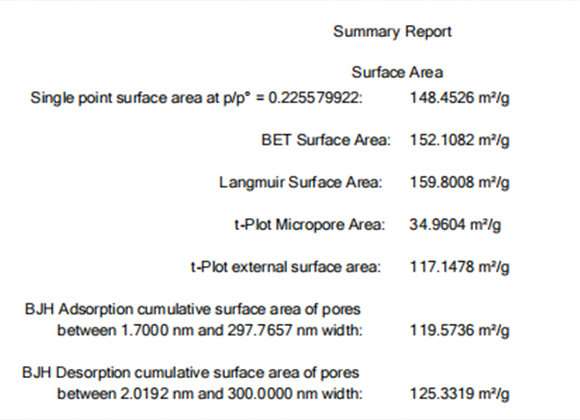

Zinc oxide white carbon black complex-20% white carbon black

Product Overview

Zinc oxide is the active agent of natural latex. Sometimes it is also used as a reinforcing agent and colorant. Zinc oxide is an important inorganic active agent in the rubber industry. Adding rubber can not only speed up the vulcanization speed, but also improve the degree of crosslinking. It has an activation effect on thiazoles, sulfenamides, guanidines, and tyuram accelerators. Used in all kinds of rubber products, zinc oxide is also an important additive for automobile tires. In addition to vulcanization, zinc oxide can improve the heat conduction properties of rubber, which helps the tire dissipate heat and ensures driving safety. Zinc oxide additives also prevent the erosion of rubber by mold organisms or ultraviolet rays.

White carbon black is used as a good reinforcing agent for synthetic rubber. Its reinforcing properties are second only to carbon black, and if it is ultra-refined and properly surface treated, it is even better than carbon black. It is especially suitable for the manufacture of white, colored and light-colored rubber products. It is used as a thickener or thickener, a blending agent for synthetic oils and insulating paints, a light-removing agent for paints, a thixotropic agent for encapsulating materials for electronic components, a precipitant for phosphor during fluorescent screen coating, a filler for color printing film, and a mold release agent for casting.

Home

Home Product Center

Product Center Telephone

Telephone Message

Message