Key Features

Ultra-high oxygen ion conductivity: 8% Y2O3 is doped to optimize the oxygen vacancy concentration, and the conductivity (800℃) can reach 0.12~0.15S/cm. It is an ideal electrolyte material for solid oxide fuel cells (SOFC).

Excellent high temperature stability: the cubic phase structure is stable to more than 1000℃, avoiding volume changes caused by monoclinic/tetragonal phase transition, and is suitable for thermal barrier coatings (TBCs) and high temperature sensors.

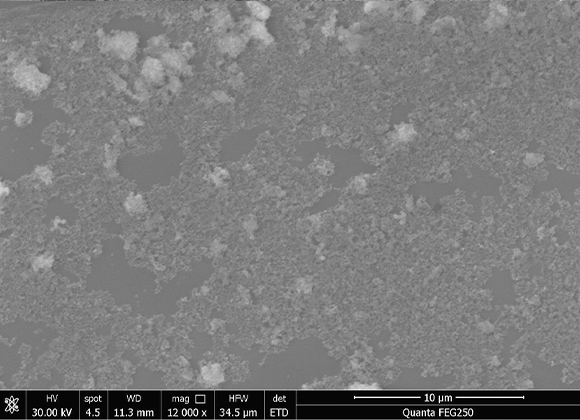

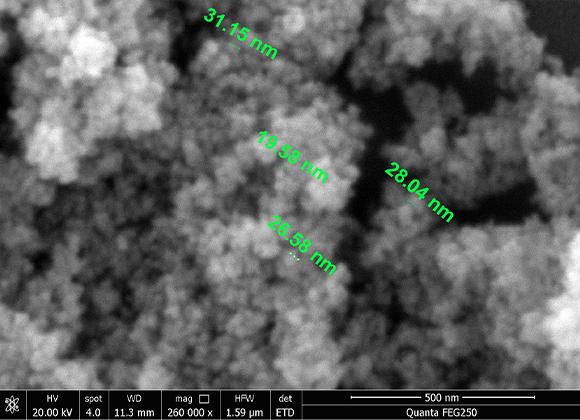

Nano-size effect: The particle size of 30 nm confers higher sintering activity and can be densified at low temperature) and mechanical properties (improved fracture toughness).

Chemical and biocompatible: resistant to acid and alkali corrosion, some medical-grade products can be used for dental repair or biological coating.

Application Area

Energy materials:

SOFC/SOEC electrolyte (low resistance, high durability)

Oxygen sensor (automobile exhaust gas monitoring, industrial process control)

High temperature coating:

Thermal barrier coating (TBCs) aviation engine, gas turbine components)

Corrosion-resistant coating (chemical reactor, nuclear industry protection)

Precision ceramics:

High light transmittance ceramics (fiber optic connectors, laser windows)

Structural ceramic reinforced phase (AlOO//ZrO 复合材料 composite material)

Electronics and catalysis:

Dielectric materials (MLCC, microwave dielectric ceramics)

Catalyst carrier (high specific surface area, anti-sintering)

Home

Home Product Center

Product Center Telephone

Telephone Message

Message